Across the nutraceutical industry, powdered supplements have consistently provided effective, consumer-loved solutions for a wide range of nutrients. The global powdered dietary supplements market was valued at $27.9B in 2025. Powders offer gram-level servings and superior bioavailability, and the Powdered Supplement Manufacturing Process ensures precise dosing, quality control, and consistent product performance.

The global powder dietary supplements market is heading toward $51.7 billion by 2030, growing at 10.9% annually. That’s not just random growth. It’s driven by real consumer preference across all age groups: 53% of Gen Z, 43% of Millennials, and 41% of Gen X regularly use supplements in powder form.

For brand owners thinking about launching powder products, understanding how these supplements actually get made is crucial. This guide breaks down the entire manufacturing journey from initial concept through final production, so you’ll know exactly what to expect when working with supplement manufacturers.

Reasons Powder Supplements Dominate the Industry in 2025

There’s a reason powders haven’t gone anywhere despite all the new delivery formats hitting the market. First, they offer unmatched dosage flexibility. A capsule holds about 500mg, while tablets max out around 1 gram. But powders? They can deliver 5, 10, even 20+ grams per serving without asking consumers to swallow handfuls of pills.

Second, consumers believe powders absorb better. Whether that’s always scientifically accurate doesn’t matter as much as the perception itself. People trust that powders work faster because they don’t need to break down before absorption starts. This perception drives purchasing decisions across multiple supplement categories.

Third, the variety is incredible. Protein blends, pre-workout formulas, greens mixes, collagen peptides, and electrolyte drinks all work in powder form. When you partner with experienced powder supplement manufacturers, you can create products that genuinely stand out in crowded markets while meeting specific consumer needs.

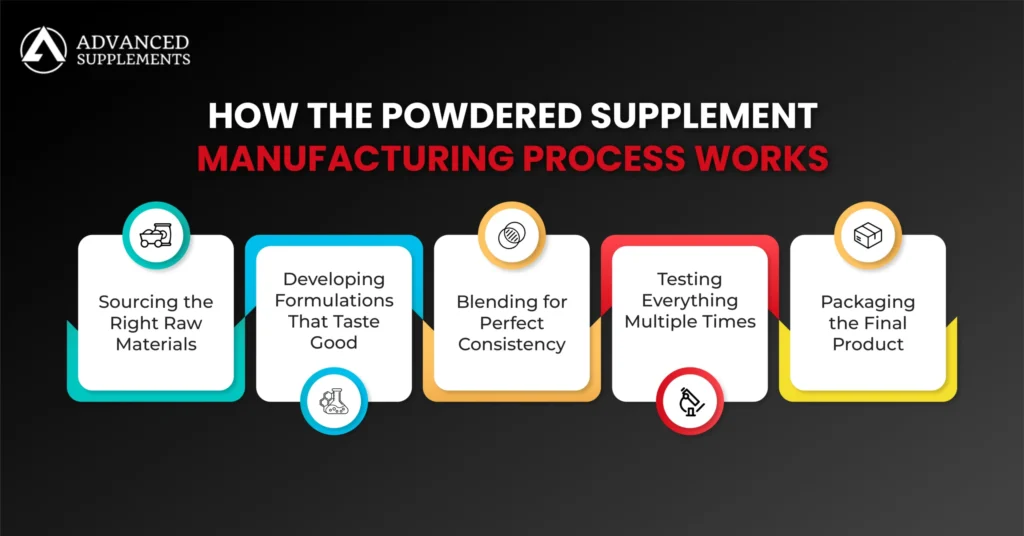

How the Powdered Supplement Manufacturing Process Works?

Manufacturing powder supplements isn’t just mixing ingredients together and calling it done. The Powdered Supplement Manufacturing Process follows a detailed procedure that ensures quality, safety, and consistency in every batch. Here’s what happens behind the scenes.

1- Sourcing the Right Raw Materials

Everything starts with ingredient selection. This is where quality either gets built in or compromised from the start. The best manufacturers source materials from GMP-audited suppliers who provide complete documentation proving identity, purity, and safety. According to FDA regulations, this verification isn’t optional; it’s required.

Beyond the active ingredients, flavor systems matter tremendously. Natural, artificial, or blended flavoring agents get paired with appropriate sweeteners to create products people actually want to drink. You can have the most effective formula in the world, but if it tastes terrible, nobody’s buying it twice.

2- Developing Formulations That Taste Good

This is where many brands either succeed or fail. Creating a powder supplement that delivers results AND tastes great requires real expertise. Working with custom powder manufacturing facilities that have in-house flavor labs makes all the difference here.

Chocolate, vanilla, and berry profiles dominate protein powders. Pre-workouts lean toward citrus and tropical flavors. The trick is masking any bitter or unpleasant notes from active ingredients without compromising their effectiveness. Good manufacturers test multiple variations during development so you can fine-tune sweetness, intensity, and aftertaste before committing to full production.

Texture matters too. Products should mix smoothly without creating clumps or excessive foam. The mouthfeel needs to match consumer expectations for the category. These details separate products that generate repeat purchases from ones that collect dust in pantries.

3- Blending for Perfect Consistency

Once the formulation is locked in, precision blending ensures every serving contains exactly what the label promises. Each ingredient gets weighed using calibrated scales with strict documentation for compliance under 21 CFR Part 111.

Manufacturers choose equipment based on the specific formula. Ribbon blenders work great for high-capacity batches with similar ingredient densities. V-blenders handle gentle mixing of sensitive ingredients. High-shear mixers tackle formulations needing aggressive homogenization. Before moving to packaging, quality teams verify the blend is uniformly distributed throughout the entire batch.

4- Testing Everything Multiple Times

Quality control runs through the entire process, not just one checkpoint at the end. Raw materials get tested before entering production, including identity verification, potency checks, and contamination screening for heavy metals, pesticides, and microbiological issues.

During blending, teams monitor bulk density, particle size, and moisture content. Finished products undergo sophisticated analytical testing including HPLC for ingredient verification, ICP-MS for heavy metal detection, microbiological testing for safety limits, and protein analysis for amino acid profiles in protein-based formulas. The NSF GMP certification standards outline these testing requirements in detail.

5- Packaging the Final Product

The last stage transforms bulk powder into retail-ready products. Automated filling lines ensure accurate weights and consistent dosing. Popular formats include bottles and tubs for traditional products, stand-up pouches as lightweight alternatives, single-serving sachets for convenience, and bulk bags for wholesale distribution.

Labels must meet all FDA requirements including supplement facts panels, ingredient lists, allergen declarations, and necessary disclaimers. Products get tamper-evident seals, lot numbers, and expiration dates for traceability. Then everything gets packed into cases and shipped to fulfillment centers.

How to Choose the Right Powder Supplement Manufacturing Partner?

Choosing who manufactures your products can make or break your brand launch. Look for facilities with dedicated powder supplement manufacturing equipment that can handle your batch sizes. Modern blending equipment and particle engineering capabilities signal a manufacturer can optimize your formulation properly.

The best partners employ food scientists, nutritionists, and flavor chemists who genuinely understand powder development. Verify they hold third-party GMP certification and check their FDA inspection history. Ask about their analytical testing capabilities and stability testing programs that ensure products maintain potency throughout shelf life.

Understanding minimum order quantities matters for budgeting both initial runs and reorders. Production timelines typically range from 4-12 weeks depending on formula complexity. Consider whether the manufacturer offers additional services like product development, packaging design, or regulatory support. Full-service partners simplify operations significantly for emerging brands.

Stop waiting and start selling. Advanced Supplements makes it easy to create high-quality powdered supplements with expert guidance, fast turnaround, and full support. Launch your brand with confidence today.

Powder Supplement Manufacturing Problems and Prevention Tips

Even with experienced manufacturers, certain challenges pop up regularly. The most common complaint about powder supplements relates to taste. That’s why facilities with in-house flavor labs and extensive testing protocols provide such advantages. Understanding common mistakes when manufacturing powders helps prevent expensive reformulations later.

Moisture causes clumping that frustrates consumers. Proper moisture control during manufacturing, appropriate packaging materials, and anti-caking agents solve this problem. Poor solubility creates unpleasant drinking experiences, but particle size optimization and smart formulation adjustments improve mixability dramatically.

Ingredient degradation over time can cause products to test below label claims before expiration. Comprehensive stability testing programs ensure products maintain potency throughout their entire shelf life. Navigating FDA requirements, especially around structure-function claims and label formatting, requires genuine expertise that experienced manufacturers bring to partnerships.

Current Powder Supplement Manufacturing Trends in 2025

The powder supplement landscape keeps evolving with several trends worth noting. Consumers increasingly demand products free from artificial ingredients, fillers, and unnecessary additives. This pushes manufacturers toward natural flavor systems and simplified ingredient decks that align with clean-label preferences.

Environmental consciousness drives the demand for sustainable packaging options, such as recyclable materials, biodegradable alternatives, and reduced plastic usage. Brands prioritizing sustainability gain competitive advantages with environmentally conscious consumers.

Novel ingredients like postbiotics, adaptogens, and nootropics create differentiation opportunities in crowded markets. Technology advances in microencapsulation, liposomal delivery, and controlled-release matrices enable more effective products with improved stability and bioavailability. Staying current with emerging supplement trends keeps product development ahead of shifting consumer demands.

Understanding Powder Supplement Manufacturing Costs

Manufacturing economics impact your ability to launch successfully. Premium, clinically-studied ingredients cost more than commodity materials, so balancing quality with commercial viability stays essential. Higher production volumes typically reduce per-unit costs as manufacturers offer tiered pricing based on batch sizes.

Packaging choices significantly affect final costs. Bottles cost more than pouches while custom packaging exceeds stock options. Third-party testing, certificates of analysis, and stability studies add expenses but protect your brand and consumers from potential issues down the road.

Simple formulations with fewer ingredients cost less to produce than complex blends requiring multiple flavor masking strategies or specialized blending techniques. Understanding what drives manufacturing cost variations enables smarter decisions throughout product development phases.

Final Insights on the Powder Supplement Manufacturing Process

Manufacturing powder supplements involves complex stages requiring specialized expertise and equipment. From raw material sourcing through precision blending to comprehensive quality control and final packaging, every step impacts market success and consumer satisfaction. The Powdered Supplement Manufacturing Process ensures these steps are executed with consistency and precision.

Partnering with experienced manufacturers who maintain GMP certification, invest in modern equipment, and employ skilled formulation teams dramatically improves your odds of creating products consumers love and repurchase. The powder supplement market’s continued growth presents real opportunities for brands willing to invest in quality manufacturing partnerships.

Focus on ingredient quality, taste optimization, regulatory compliance, and manufacturing excellence. This positions products for long-term success in increasingly competitive markets. Whether you’re launching your first formulation or expanding established lines, understanding the complete Powdered Supplement Manufacturing Process empowers better decisions that ultimately drive business success in this thriving industry.

FAQS

-

What are the common challenges in powdered supplement manufacturing?

Manufacturers often face issues like ingredient clumping due to moisture, poor solubility affecting mixability, and ingredient degradation over time. Implementing moisture control, optimizing particle size, and conducting comprehensive stability testing are essential to address these challenges.

-

How does particle size affect the quality of powdered supplements?

Particle size influences solubility, texture, and bioavailability. Smaller particles can improve dissolution rates, enhancing absorption, while larger particles may affect the product’s mouthfeel and mixability. Manufacturers use specialized equipment to achieve the desired particle size for optimal product performance.

-

What are the benefits of GMP certification in supplement manufacturing?

Good Manufacturing Practices (GMP) certification ensures that manufacturers adhere to stringent quality control standards, reducing the risk of contamination and ensuring product consistency. This certification is crucial for consumer safety and regulatory compliance.

-

How do environmental factors impact powdered supplement stability?

Factors like temperature, humidity, and light exposure can affect the potency and shelf life of powdered supplements. Manufacturers implement controlled storage conditions and use protective packaging to mitigate these effects and maintain product integrity.

-

What role does packaging play in the shelf life of powdered supplements?

Packaging protects products from environmental factors such as moisture and air, which can degrade quality. Innovative packaging solutions, like moisture-resistant pouches and airtight containers, help extend shelf life and preserve the efficacy of powdered supplements.